Atlas Copco - Understanding physics at the microscale in filter media with supercomputing

Exploration & optimisation of design at Atlas Copco

Atlas Copco specialises in the design, development and manufacture of, amongst others, industrial compressors and expanders, vacuum solutions and air and gas treatment equipment.

Customers tend to be companies in various industries, from food and beverage, oil and gas, semiconductor, transportation, and construction to medical applications.

Atlas Copco extensively uses computing, computer models and digital twins to predict the behaviour of various products in different conditions. The same models are also used to allow engineers to better understand products on a fundamental level. This accelerates the development of new and better designs. Supercomputing allows for more extensive exploration and optimisation of a design. It also permits the simulation of more physics and larger problems that were infeasible before.

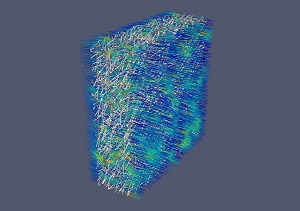

Understanding physics at the microscale in filter media with supercomputing

Tom Saenen (Atlas Copco, Technology developer Computational Fluid Dynamics): “Atlas Copco wanted to have a better understanding of microscale air and oil flow behaviour in oil aerosol filter media. If we better understand the physics at this scale, we can design filters with higher filtration efficiency at a lower pressure drop. This, in the end, results in cleaner air delivered at a lower energy cost to our customers.”

The flow geometry and physics at the microscale in filter media are complex and require state-of-the-art computational fluid dynamics techniques to resolve. The required computational resources are extensive and need world-class high-performance computing.

VSC proposed to run these calculations on the Tier-1 cluster Hortense. Simulations were first performed to build the necessary experience in efficiently running large-scale calculations and exploring the computational limits. Using Hortense gave Atlas Copco access to new simulation techniques to investigate the microscale behaviour of oil aerosol filter media.

Easy access to VSC infrastructure through a web interface

VSC aims to facilitate access to supercomputing infrastructure and therefore uses ‘open OnDemand’ , an open-source web portal.

Tom Saenen (Atlas Copco, Technology developer Computational Fluid Dynamics): “Using the VSC infrastructure was easy. We especially liked the web interface because it allowed us to access the VSC infrastructure where ever we were through a web browser. It is as easy as using a computer on-site. There’s also a very extensive software library available on the VSC.”

Positive collaboration on both sides

VSC fully supported Atlas Copco during the process and helped the company to run the computations on Hortense efficiently.

Tom Saenen (Atlas Copco, Technology developer Computational Fluid Dynamics): “During our project, Hortense was starting up, but the VSC handled requests and support always very promptly. The responses were also very to the point; thus, issues were resolved efficiently. We found the collaboration very positive.”

Ewald Pauwels (Tier-1 support VSC): “The Atlas Copco researchers immediately had specific in-depth questions on how to use the supercomputer most optimally. Our team was eager to help them and provide them with solutions.”

Tom Saenen (Atlas Copco, Technology developer Computational Fluid Dynamics): “The support team was genuinely interested in our simulation questions, problems and results. It truly felt like a collaboration to achieve the results we wanted with the simulations. The team readily shared useful insights and expertise.”

Get easy access to powerful computing infrastructure at a modest price

Tom Saenen (Atlas Copco, Technology developer Computational Fluid Dynamics): “We think that the VSC is an excellent organisation for the Flemish industry to get easy access to a powerful computing infrastructure at a modest price. It truly democratises large-scale simulations otherwise out of reach for many companies. Finally, organisations can expect quick and skilful support from the VSC team in setting up the simulations and software tools.”

Published on 15/06/2023

Tom Saenen is a technology developer in the computer-aided engineering team at Atlas Copco Airpower in Wilrijk. He has previously worked as a post-doctoral researcher at the Ecole Polytechnique Fédérale de Lausanne and obtained a PhD from the Katholieke Universiteit in Leuven. In both cases, his research was focused on multiphase evaporating flow in microchannels for electronics cooling. Before this, he obtained a master’s degree in mechanical engineering from the KULeuven. Currently, his work is aimed at improving and applying various CFD techniques to aid in the development of innovative industrial solutions and products at Atlas Copco.