Exclusive Interview – Philippe Geuzaine & Ingrid Lepot (Cenaero)

Left to right: Ingrid Lepot, Head of R&T (Research & Technology) and Philippe Geuzaine, Director of Cenaero.

To mark the opening of the 2025 Paris Air Show, EuroCC Belgium had the pleasure of speaking with Philippe Geuzaine and Ingrid Lepot from Cenaero, a key player in aeronautics and space design, and the coordinating entity behind EuroCC Belgium's activities.

At the center stage of the discussion: transformations in the aerospace and defense sectors, the technologies driving them, and the strategic role of high-performance computing (HPC), numerical simulation, quantum technologies, and artificial intelligence (AI) in this (r)evolution.

🔹 What is the current role of high-performance computing (HPC), artificial intelligence (AI), and numerical simulation in the aerospace, space, and defense sectors?

Virtual prototyping has long been a cornerstone of aeronautical development, whether in airframe design or propulsion systems. The extensive use of numerical simulation, computer-aided design (CAD), and predictive modeling has only intensified over time as tools have become more powerful and precise.

Today, integrating artificial intelligence and experimental data into these processes paves the way for a paradigm shift: significantly reducing physical testing in favor of faster, more accurate, and more cost-effective virtual iterations. HPC enables the handling of increasingly complex models, while reducing design cycle times.

The medium-term goal is to achieve a “certifiable by simulation” design approach, incorporating not only the performance of the final product but also production scenarios—before the manufacturing phase even begins.

A prime example is the DIDEAROT project (co-funded by the Horizon Europe program and coordinated by Cenaero), which explores this transition toward robust digital development for composite materials. The project focuses on two key areas:

- Manufacturing, with the prediction of distortions, residual stresses, and assembly defects for increasingly large and complex composite parts produced at industrial scale.

- Dynamic loads and impacts, with models aimed at anticipating various damage modes and resistance to repeated stresses—critical factors in certification scenarios.

The core of the project: integrating these predictive models into a robust, certifiable design process to enhance agility, reliability, and competitiveness.

🔹 Will AI, enabled by HPC, have a major impact on aerospace research in the coming years?

What is striking today is the speed at which this technology (AI) is evolving: new generative AI models are emerging every two months. No other technology has been adopted this rapidly. In terms of design, we still cannot fully gauge how much this type of approach will accelerate cycles or on what timeline.

The future will be not only digital but cognitive. The explosion of data must be mastered through transparency—on captured data, associated uncertainties, and data processing logic—so that humans can retain controlled use of AI's power. This goes beyond technology and becomes a societal issue.

In terms of design, AI-assisted dynamic optimization—particularly through machine learning (supervised, unsupervised, reinforcement, and transfer learning)—is a foundational research area for Cenaero.

Our vision is that future design systems will be agent-based and must fully harness the power of domain-specific AIs. These AI agents will need to collaborate through data sharing and dynamic (re)configuration of their interactions. Decision-making capabilities in partnership with human designers—progressing toward increased autonomy of AI agents and personalized interactions—will be critical. This involves reinforcement learning with human feedback.

Much is said about “Deep Learning,” but in the design context, what's truly essential is the agile implementation of “Deep Collaboration” between AI agents. This is key to automating complex workflows and answering multifaceted questions by integrating heterogeneous data and knowledge from the company and its partners.

The hybridization of numerical simulation and AI is a powerful driver for accelerating technological innovation—vital in the aerospace sector. And the synergy with physical testing goes far beyond validation or calibration of numerical models. Designing more representative tests, optimizing test matrices, sequentially and actively assimilating experimental data, and dynamically controlling physical systems will all contribute to a complete synergy between a physical system and its digital twin.

🔹 Do you foresee new opportunities from the combined use of AI and HPC in applied aerospace and defense research?

Absolutely! Cenaero has long been recognized for its expertise in multidisciplinary turbomachinery design and optimization, relying on numerical simulation tools with multiple fidelity levels and integrating high-fidelity only when physically necessary.

This expertise is showcased through participation in major European projects such as OFELIA (Open Fan for Environmental Low Impact of Aviation) and HE-ART (Hybrid Electric propulsion system for regional AIRrcrafT), supported by the Clean Aviation Joint Undertaking. HPC capabilities are essential for deploying numerical methods to meet challenges in energy efficiency and sustainability.

The growing integration of AI into multi-scale modeling opens entirely new perspectives. Two European projects, in which Cenaero is a partner, exemplify this:

- Sci-Fi-Turbo (Scale-resolving Simulations for Innovations in Turbomachinery Design), which aims to integrate scale-resolving aerodynamic simulations into the design process.

- ROSAS (RObust simulation Systems exploiting AI-based turbulence models and high-fidelity algorithmS), which focuses on combining AI with the latest advances in turbulence modeling to optimize physical testing and speed up the design optimization process.

These projects merge traditional physical simulation with machine learning algorithms to improve model accuracy, speed, and reliability—and to integrate them into a design optimization loop.

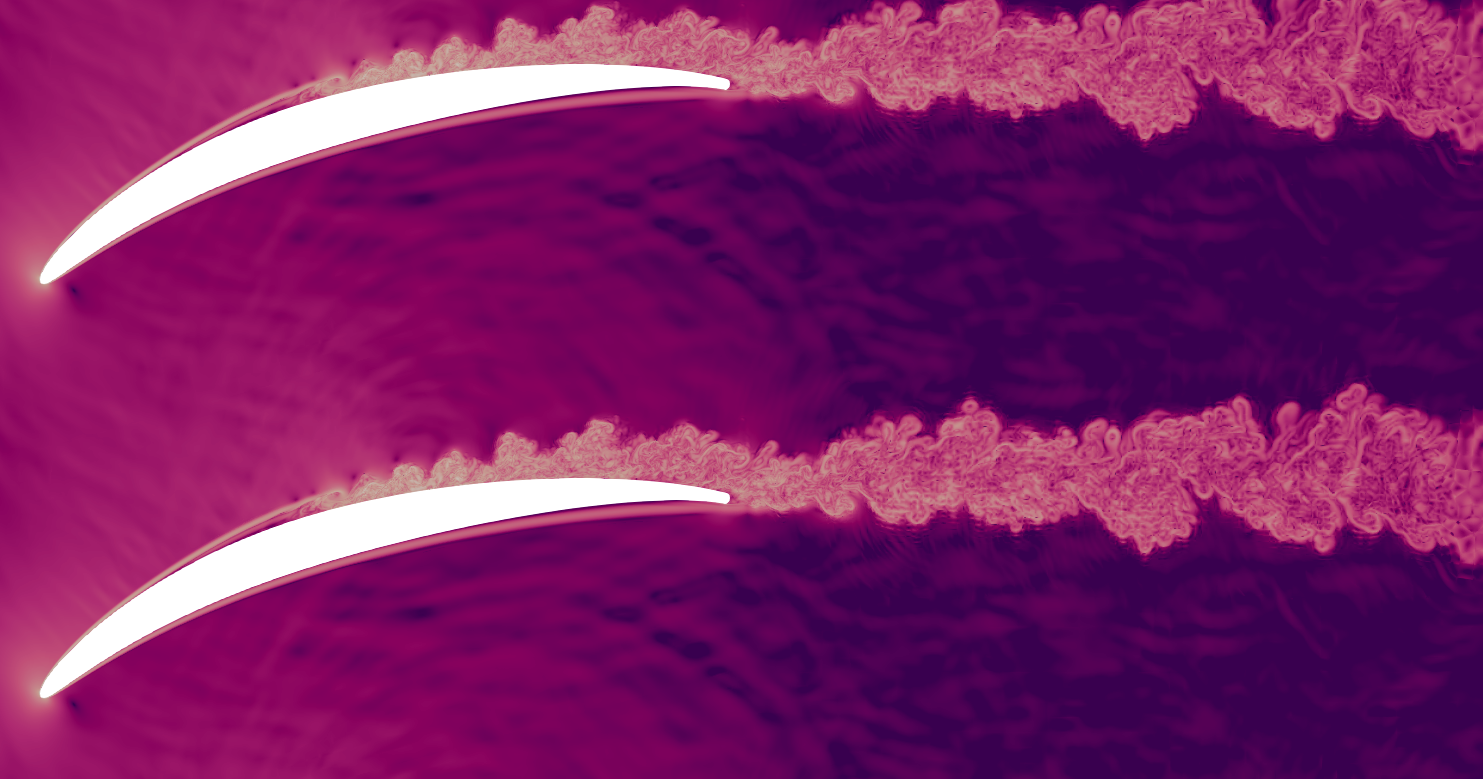

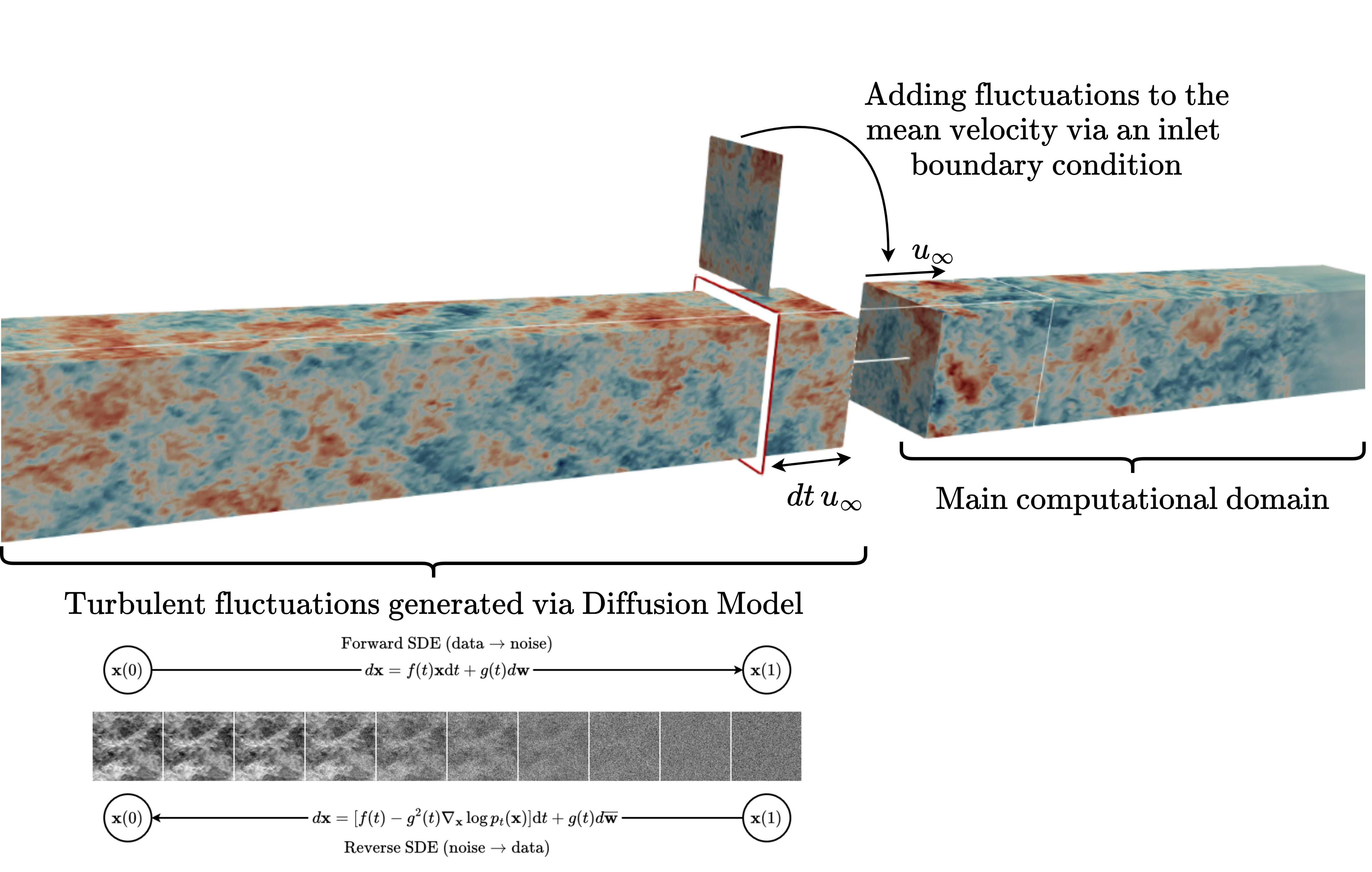

As part of the Sci-Fi-Turbo project, Cenaero carried out scale-resolving aerodynamic simulations of a low-pressure compressor blade developed by the Institute of Propulsion Technology at DLR in Cologne [Figure 1]. These simulations complement physical testing by providing insight into complex flow phenomena. They also help enhancing standard simulation practices and tools based on RANS models, resulting in more reliable design processes for the next generation of turbojet engines. Since injecting a physically realistic turbulent inlet flow is key for this type of simulations, Cenaero developed a novel inflow condition generation method based on a deep generative diffusion model [Figure 2] in the ARIAC project (Applications and Research for Trusted Artificial Intelligence) supported by the Walloon Region.

🔹 Quantum computing is getting increasing attention (and is a featured topic at the 2025 Paris Air Show). What is your perspective on this technology and its potential medium- or long-term impacts in your field?

Cenaero initiated its first quantum project within the VirtualLab initiative supported by the ERDF. In this context, we are developing design tools that optimize material distribution by placing the right material in the right place—while respecting strict material budget constraints, which are critical in the aerospace sector.

The quantum computing approach we are exploring through the VirtualLab project could revolutionize our design tools by allowing us to find global optima in material layout, thanks to its ability to simultaneously explore vast configuration spaces. This could open a new era for optimization in connection with additive manufacturing.