User Story Achieving Optimal Compressor Design with AI Techniques Thanks to HPC

In aeronautics, every fraction of a percentage in efficiency matters. A small improvement in engine performance can save millions of litres of fuel over an aircraft fleet’s lifetime — and avoid vast amounts of CO₂ emissions. Yet the path to such gains is neither straightforward nor forgiving.

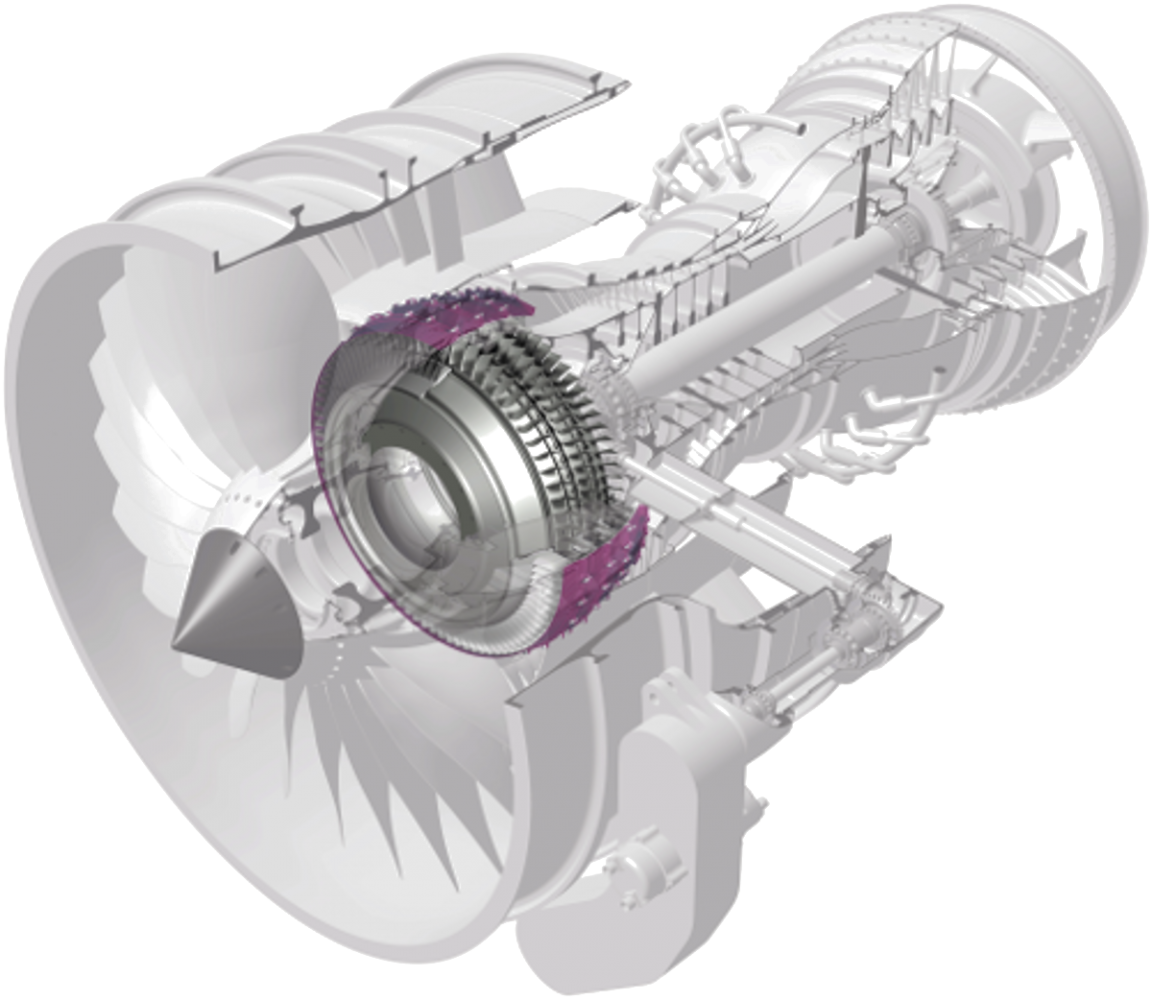

For Safran Aero Boosters (SAB), pushing the limits of compressor performance meant tackling one of the most intricate engineering puzzles in the industry: the design of a multi-stage compressor. These components are the heart of the engine’s compression system, operating under extreme conditions and involving hundreds of interdependent geometrical parameters — each capable of influencing efficiency, stability, and manufacturability.

"Exploring such a vast design space without computational help would be like trying to map the ocean with a rowboat," reflects Rajan Filomeno Coelho, Senior Research Engineer at Cenaero. "We needed a way to navigate complexity at scale."

The challenge is not simply finding one good design — it is exploring thousands of possibilities to discover the best. That requires Computational Fluid Dynamics (CFD) simulations, each predicting how a compressor geometry will behave under real-world conditions: pressures, velocities, shock interactions, and aerodynamic losses. But CFD is computationally demanding. Running the required thousands of simulations would take months, even years, on conventional computers. The scale of the task meant HPC was the only viable route.

Dimensionality reduction to tame hundreds of parameters

Within the WINGS project, supported by the Walloon Region, Cenaero explored an AI-driven approach to simplify the design problem: dimensionality reduction. Starting from a dataset of CFD results, the team applied UMAP (Uniform Manifold Approximation and Projection) to project the high-dimensional parameter space into a more tractable representation, and then used DBSCAN to cluster geometrical parameters that show similar influence on simulation outputs.

The principle is surprisingly effective: parameters that behave similarly can be grouped together, reducing the number of independent variables the optimizer must explore. That reduces the search space while preserving the essential physics that determines compressor performance.

This workflow was deployed inside Minamo, Cenaero’s in-house optimisation and parametric-study platform, enabling engineers to run the dimensionality reduction, link clusters to design variables, and feed the reduced parameter set to surrogate-based and direct optimisation routines.

"By clustering parameters that behave alike, we can shrink the search space without losing accuracy," explains Rajan. "This makes optimisation feasible at a scale that was previously out of reach."

Lucia: turning weeks into days

High-performance computing was instrumental to the project’s success. On Lucia Supercomputer, a full optimisation loop that would have required weeks on a workstation now runs in under 36 hours. This dramatic acceleration enables rapid iteration, extensive validation, and a level of exploration that changes how engineers approach the design space.

"HPC doesn’t just make things faster," Rajan emphasises. "It allows us to think differently — to attempt designs we might never have considered if computation was a bottleneck."

From lab to industry — and to a greener future

The project produced benefits at multiple levels. Scientifically, it validated an AI-driven dimensionality reduction pipeline for aeronautical applications; results were presented at the ASMO/ISSMO conference in July 2024. Industrially, the methodology provides Safran Aero Boosters with a practical way to explore design options that meet both aerodynamic and manufacturing constraints, while Minamo’s interface make results and sensitivity analyses accessible to engineers. Environmentally, improved compressor designs can incrementally reduce fuel burn and CO₂ emissions over the operational life of engines.

The project also demonstrates a collaborative model: combining domain expertise in turbomachinery, advanced AI methods, and HPC infrastructures to tackle problems that no single discipline could solve on its own.

Looking forward

As AI techniques and HPC capabilities continue to evolve, their integration into engineering workflows will deepen. The dimensionality reduction approach developed here is not limited to compressors: it can be applied to other turbomachinery components or complex systems where hundreds of interacting parameters must be managed. For the aeronautical sector — driven by the twin needs of performance and sustainability — such tools will be central to designing the next generation of greener engines.

"The synergy between AI, HPC and engineering design is still in its early days," Rajan concludes. "But its potential is enormous — and we’re just beginning to tap into it."

The research mentioned in the user story led to a publication :

Filomeno Coelho, R., Sainvitu, C. & Benamara, T. Dimensionality reduction combining variable grouping and UMAP for structural optimization. Struct Multidisc Optim 68, 106 (2025). https://doi.org/10.1007/s00158-025-04028-5

Published 02/10/2025

Rajan Filomeno Coelho

Rajan Filomeno Coelho holds a Master’s Degree in Civil Engineering (2000), and a PhD in Applied Sciences (2004), both obtained at the Université libre de Bruxelles (ULB). He has been working in R&D on numerical optimization methods for aerospace, aeronautical, automotive, and architectural applications. He is also the co-founder of Kabandy, a spin-off of the ULB focused on the digitalization of the building sector (2016). He is now Senior Research Engineer in Cenaero, within the Optimization & Machine Learning group.